How we improved driver productivity by 70+% and reduced the cost of sorting and loading each parcel by 9p before leaving the depot

Overview

A proof of concept was requested by a sub depot operator who has contracts with a major next day parcel delivery business.

The challenge was to produce a tool that would speed up the morning sort and load for experienced drivers, who may have to cover new routes during holidays and sickness. In addition, it was to help inexperienced drivers become efficient as quickly as possible inorder to reduce the attrition rate of 80% .

Site Visit

Our team spent several days shadowing the drivers in the depot to fully understand the daily challenges being faced, both in the depot and out on the road delivering 150 parcel runs.

The Solution Developed

- Enables driver’s to manage missing barcodes and address data with minimal keystrokes

- Generates a geospatial route out and back to the depot

- Minimises the number of stops needed

- Orders parcels so they can be easily stored and retrieved in the vehicle

- Minimises the driving distance

- Pinpoints the delivery address

Sort and load

A daily challenge for any driver taking on a new round. We remove the need for local knowledge and experience by geospatially organising and numbering the run.

Route optimisation

Maximise the utilisation of your fleet and reduce the over all miles driven by introducing geospatial location and dynamic routing to your operation

Finding locations with pinpoint accuracy

Enable drivers to find multiple locations, first time, every time, without taking their eyes off the road in any light or weather conditions.

The Trial

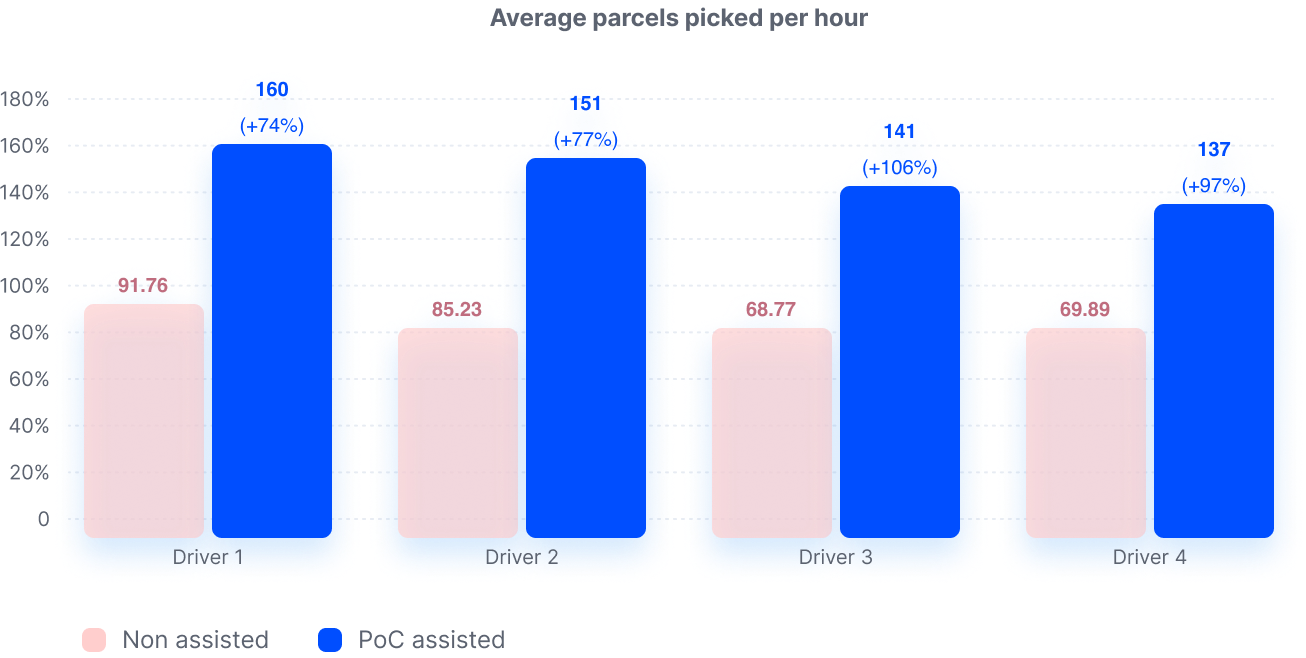

We conducted a seven week trial (6 weeks of data collection and 1 week of testing in week 3), with four seasoned drivers who knew their own routes well, to see the effectiveness of the sort and load element of the tool on the process which takes place each morning, prior to the drivers leaving the depot.

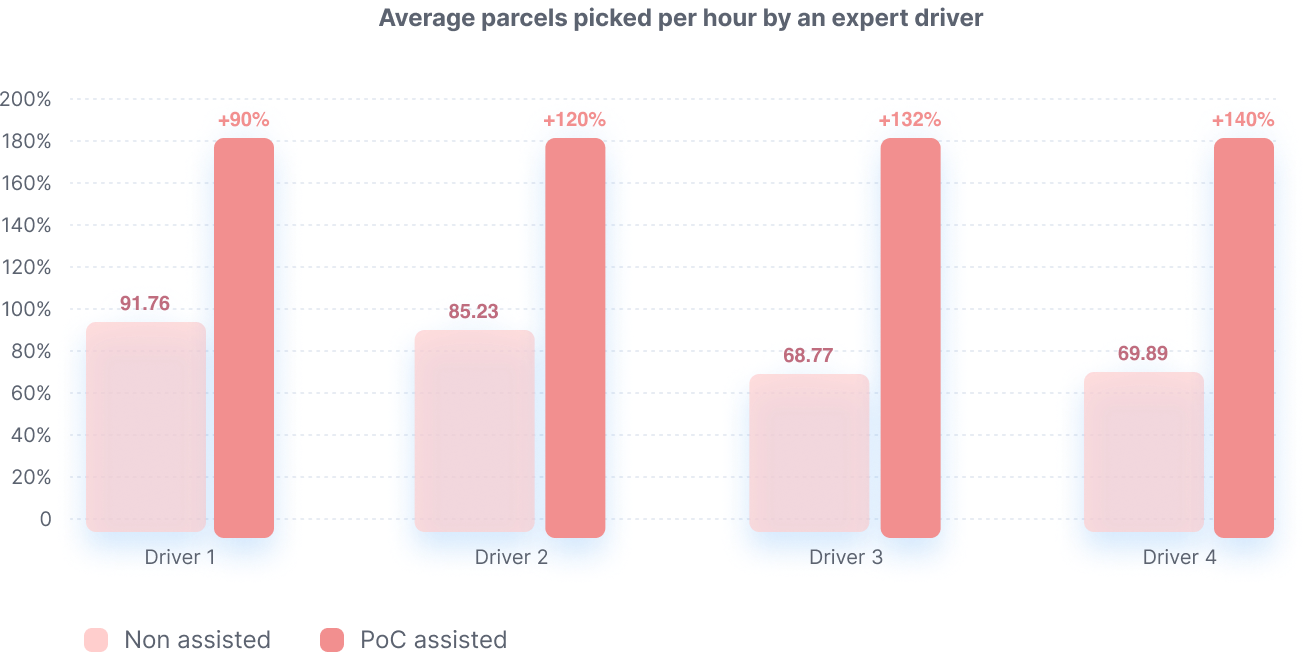

As a control mechanism we used an Expert Driver with 25 years experience to shadow the drivers on set weeks.

We had hoped for a 10% productivity improvement, equating to a 5% cost saving per parcel loaded.

What actually was achieved proved infinitely more impressive.

The Metrics

Each driver was timed sorting and loading his daily run for six days a week over a two-week period. This gave us an average load rate per parcel per hour.

These differed by driver depending on experience and ability. They were asked to time themselves performing these actions as they would in any normal day of their working life. This exercise is shown as weeks one and two on the attached matrix.

Week three was set aside for all 4 drivers and our shadowing Expert Driver to familiarise themselves with the tool, before using it for two of the following four weeks of the trial.

Weeks Four to Seven inclusive were set aside, to allow us to time the four drivers carrying out the same daily “sort & load” actions as they had performed in weeks one and two, but this time two of these weeks each driver would have the use of the sort and load tool. This meant that each driver had been timed for a total of four weeks carrying out the load as normal, and two weeks carrying out the same tasks supported by the tool. This gave us the average parcels sorted & loaded on a normal day versus the average parcels picked & loaded when supported by the tool.

The Results

We set our Expert Driver the task of “Shadowing” all four drivers for one week each. He would start one hour earlier than the driver each day for the full six days in that week. He would Sort & Load that drivers run for the day with the help of the tool, timing himself accordingly. When finished, he would unload the van, putting the parcels back exactly as he found them, awaiting the actual driver to carry out his exact same daily routine without the use of our product. This enabled us to measure the time taken to sort and load the exact same parcel run twice in the same day with and without the product. He shadowed Driver One in week 4, Driver Two in week 5, Driver Three in week 6, and Driver Four in week 7.

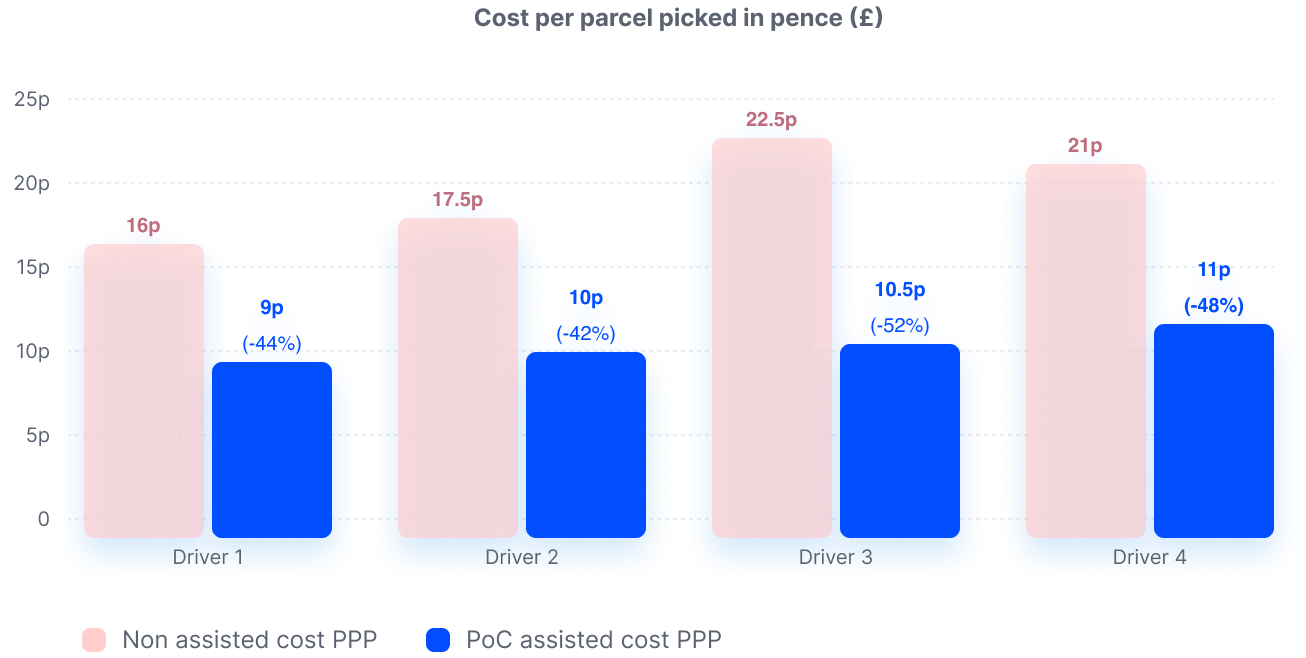

To monetise our results we have estimated the average driver costs £15/hr (salary,holiday pay, N.I) and have applied this rate to the time spent on the sort and load element of the day. The graph below clearly demonstrates substantial savings across each driver.

Explore our Drive Trial results

Why talk to us?

Become an early adopter of tools that generate competitive advantage for your business

We would like to talk with business’ that have complex, daily multi drop or multi collection challenges and are interested in deploying “next generation” tools to better serve their people and customers

Develop compelling ESG (Environmental, Sustainability & Governance) propositions

Generate real-time business intelligence to make better business decisions, gain higher consumer ratings and comply with existing and future legislation.

Partner with domain experts in the multi drop & multi collection industries

Our decades of hands-on experience in multi-drop and the delivery of digital solutions for real world challenges make us the innovation team to partner with for tactical and strategic solutions.